Engineering Durability: How Floor LED Screens Withstand Heavy Foot Traffic

Core Construction and Structural Reinforcement of Floor LED Screens

LED floor screens built for busy areas typically have several layers including strong aluminum frames and polycarbonate grid supports. The connectors used here are rated at military grade levels and can handle around 5 million compression cycles according to ASTM F2097-21 testing standards. This helps keep everything mechanically sound over time. To stop tiles from shifting sideways when people walk across them, there's an interlocking system in place. On top sits 8mm thick tempered glass attached to silicone that spreads out impacts. Together these components create one solid unit that stays clear and visible even after years of constant foot traffic.

Principles of Wear Resistance in High-Traffic LED Floor Systems

At the molecular level, wear resistance comes from special nano-ceramic coatings which cut down on surface friction by around 62% when compared to regular materials. A recent study published in Tribology International backs this claim up. The newer versions come with self healing polymer layers too. These actually fix small scratches when temperatures rise above 15 degrees Celsius. Plus there are anti static treatments built in to stop dust and grit from sticking so easily. When tested with constant brushing forces, these coated surfaces still maintain about 92% brightness even after going through 10 thousand simulated footsteps. That's pretty impressive considering they beat standard LED flooring options by roughly three times in performance tests.

Key Role of Impact Absorption and Load Distribution Design

The secret behind impact resistance lies in those hexagonal honeycomb structures that spread out force so it doesn't damage delicate electronics inside. These panels can actually handle pretty heavy stuff too – we're talking about supporting around 2,000 kilograms per square meter. To put that in perspective, imagine twelve grown adults all standing on just one square meter of space. Between the LED clusters there are these special neoprene cushions that really cut down on shock waves when something hits hard. They manage to lower those intense G-forces by almost 80 percent during unexpected collisions. And let's not forget about those clever expansion gaps built right into the materials. They give everything room to move naturally as temperatures change, yet still keep water out completely.

Understanding Load Ratings and Pressure Tolerance Standards

Commercial floor LED screens must meet strict load-bearing criteria to ensure safety and performance longevity. Top-tier systems support 1,500–2,500 kg/m², with premium industrial models exceeding 3,000 kg/m². Performance benchmarks are categorized by application:

| Application | Static Load Range | Dynamic Load Range |

|---|---|---|

| Retail spaces | 1,200–1,800 kg/m² | 800–1,200 kg/m² |

| Concert stages | 2,000–2,500 kg/m² | 1,500–2,000 kg/m² |

| Transportation hubs | 2,500–3,000 kg/m² | 2,000–2,500 kg/m² |

These ratings align with ISO 20957-10:2023 standards, adapted for sustained pedestrian and equipment loading.

Impact and Crush Resistance Testing for Commercial Floor LED Screens

The durability gets tested according to MIL-STD-810G standards which simulate all sorts of real world stresses. Think about things like a 125kg point load from those sharp stiletto heels with their tiny 3mm contact area, or the heavy 400kg per square meter rolling loads when service trolleys pass over. There are also thousands upon thousands of compression cycles that mimic how products get used day after day for years at end. For front surfaces, we have IP65 protection against dust and water getting inside, so they stay clean and functional even in tough environments. The tempered glass or polycarbonate covers resist scratches really well too, hitting that impressive 9H level on the Mohs scale. And UL certified versions can handle quite a punch too – around 5 joules of impact energy, basically what happens if someone drops a 10kg object from half a meter height onto them. Amazingly enough, this kind of abuse doesn't seem to affect the pixels at all.

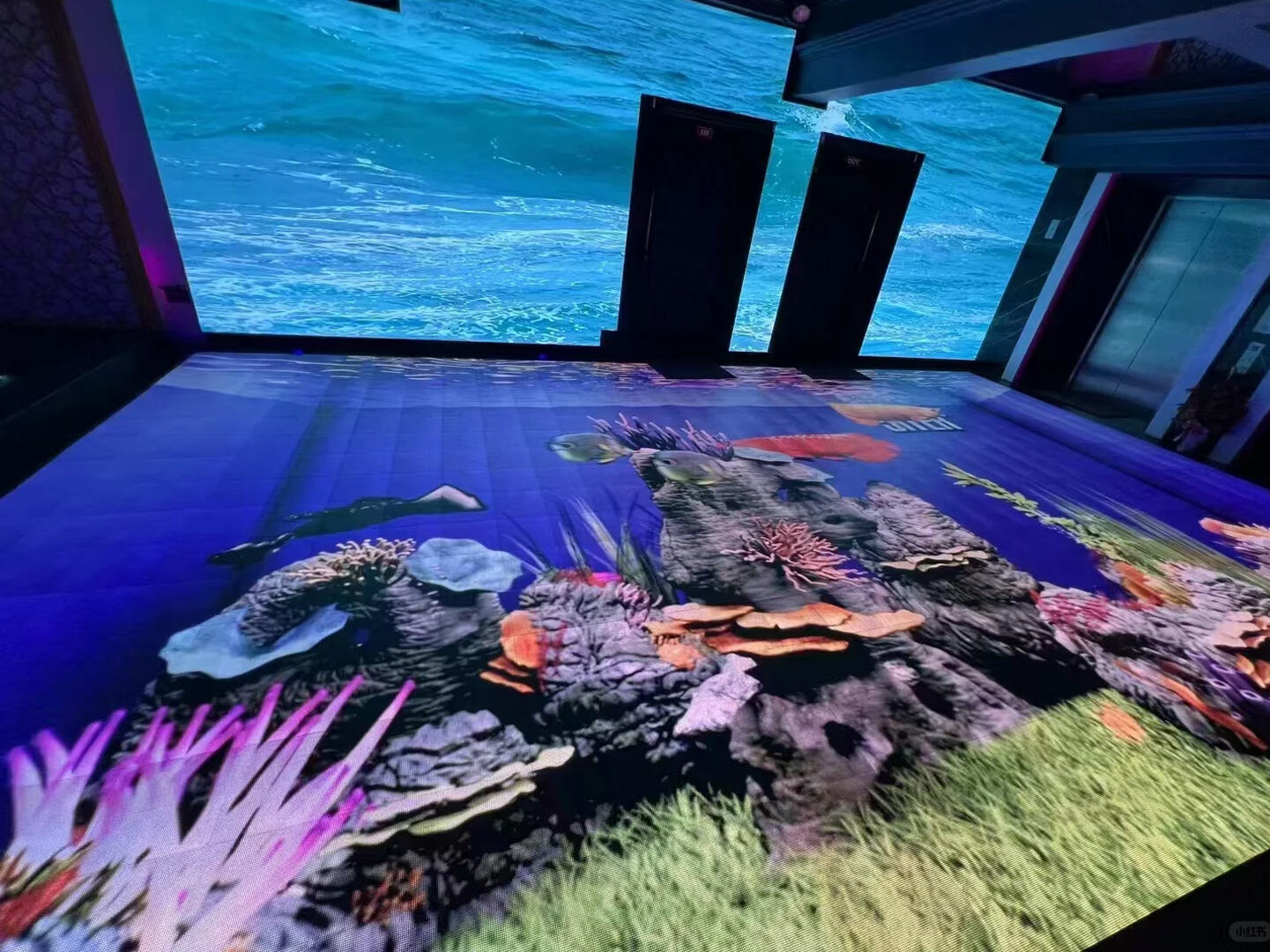

Real-World Performance on Stages, Runways, and Public Floors

At CES 2023, a 600m² LED floor endured daily visits from over 23,000 attendees (average weight: 83 kg), recording only 0.12% pixel failure across 14 days. In transportation settings like Dubai Metro, installations maintain 92% brightness retention after 18 months of 24/7 operation, enabled by automatic load-balancing algorithms that dynamically redistribute pressure across 256 sensing zones per panel.

Surface Materials and Anti-Scratch Technologies in Floor LED Screens

Tempered Glass vs. Polycarbonate: Material Trade-offs for Durability

When looking at surface materials for displays, tempered glass and polycarbonate stand out with their unique benefits. Tempered glass really holds up against scratches, keeping its clear appearance even after tens of thousands of feet walked across it in stores according to tests from the Digital Display Institute last year. But this material does have a weakness when something hits it hard enough, around 500 pounds per square inch or more, which can cause cracks because glass just isn't very flexible. On the other hand, polycarbonate takes a lot more punishment before breaking. It has about twice the strength needed to withstand those rough conditions we see at concerts and trade shows where big rigs get moved around constantly. The downside? Those same surfaces tend to show tiny scratches over time that aren't always easy to notice but definitely build up.

Material selection should reflect usage patterns:

- Tempered glass is preferred in museums and interactive exhibits where visual fidelity and scratch resistance are critical

- Polycarbonate is better suited for modular setups requiring forklift access or frequent reconfiguration

Anti-Scratch Coatings and Surface Treatments for Longevity

Ceramic nano coatings cut down scratches by around three quarters when compared to regular surfaces without any treatment. They form bonds at the molecular level measuring between five to ten microns thick, which helps them stand up against all that shoe dirt and constant rubbing from suitcases. In really tough spots such as those busy airport check in counters, we often see a mix of different treatments applied together. The base layer usually contains something called diamond like carbon or DLC for extra toughness, while the top layer has properties that make it resistant to oil stains and most common cleaning products. Maintenance is pretty straightforward too – just need to recoat once a year or so. Field tests at various metro stations show these coated surfaces keep about ninety two percent of their original brightness even after eight to twelve years of non stop use in high traffic areas.

Environmental Protection and Operational Stability in Demanding Conditions

IP Ratings, Dust, and Moisture Resistance for Indoor High-Traffic Zones

Most high performance floor LED displays come with at least IP65 protection ratings, which means they keep out nearly all airborne dust particles bigger than 50 microns and resist low pressure water sprays. These specs make them work well in places where dust is a problem like busy shopping centers, as well as areas around food courts and indoor swimming pools that tend to get damp. Testing has actually demonstrated something pretty impressive too. When manufacturers put IP68 rated panels through 48 straight hours of sand blasting conditions similar to what might happen during regular cleaning in a mall over five years, none of the pixels failed despite constant exposure to abrasive materials.

Thermal Management and Humidity Tolerance in Malls and Entertainment Venues

Modern floor displays come with phase change materials and aluminum cold plates built right in, allowing them to work consistently across temperatures ranging from minus 20 degrees Celsius all the way up to 55 degrees Celsius. This kind of temperature tolerance is really important for places where there's constant switching between packed events during the day and thorough cleaning at night. The driver integrated circuits get extra protection through special coatings that resist moisture buildup, stopping those pesky conductive dendrites from forming even when humidity hits around 95%. After running through rigorous temperature and humidity bias tests simulating actual monsoon conditions for over 1,000 hours straight, these displays maintain their brightness level at about 98% of original output, which speaks volumes about their durability under extreme weather scenarios.

Proven Applications and Reliability of Floor LED Screens in Real-World Settings

Interactive LED Floors at Major Events: Olympics and Global Concerts

Floor LED screens really hold up in those big moments like Olympic opening ceremonies, where dancers and performers move across them while carrying weights sometimes over 800 pounds per square foot. What makes these floors so dependable is their reinforced structure plus materials that resist impacts without cracking or breaking down mid-show. A recent look at the live events sector from late 2023 showed something interesting too many event planners said their LED floors never had any problems at all during concerts and stadium shows. Around three out of four organizers who used these special IP68 rated modular systems didn't experience even a single second of downtime throughout entire tours lasting months on end.

Long-Term Performance in 24/7 Retail, Bars, and Transit Hubs

Floor LED screens installed in busy places like airports, big department stores, and casinos typically last well beyond five years even when they face upwards of 10,000 people walking across them every day. The secret? Special anti-scratch coatings combined with backup power systems keep these displays looking bright and consistent at around 98.3% brightness according to the latest AVIXA benchmark from 2024. For casino operators specifically, switching to those specially treated LED panels designed for non-stop use makes a real difference in their bottom line too. One major Las Vegas property saw maintenance expenses drop by about 40% after replacing old fashioned flooring with these modern LED solutions.

Evaluating Marketing Claims: Are “High-Stability” Floor LED Screens Trustworthy?

Independent tests have found big differences between what manufacturers claim and what these products actually deliver in real world settings. Take LED flooring for instance: most of them pass the EN 14348 hygiene standard, around 92% if we go by UL Solutions numbers from last year. But when it comes to handling those heavy forklifts? Only about two thirds can really take that 15 ton weight as promised. Smart shoppers want to work with companies that openly share their certification papers and can show they've been around for at least seven years doing similar jobs somewhere else. This kind of background check helps separate the genuine performers from the ones who just sound good on paper.

FAQ

How do floor LED screens resist wear and tear from heavy foot traffic?

Floor LED screens use nano-ceramic coatings to reduce surface friction significantly, and self-healing polymer layers to repair minor scratches. They also incorporate anti-static treatments to minimize dust and grit accumulation, maintaining high brightness even after extensive use.

What materials are used in floor LED screens to ensure durability?

Floor LED screens typically use tempered glass or polycarbonate with additional nano-ceramic coatings to resist scratches and impacts. Tempered glass is favored for its scratch resistance, while polycarbonate is chosen for areas requiring higher impact resistance.

Can floor LED screens withstand heavy loads?

Yes, commercial floor LED screens are designed to handle significant weights, supporting between 1,500–3,000 kg/m². They also undergo rigorous testing to ensure they can withstand point loads from sharp objects and rolling loads from equipment.

Are floor LED screens suitable for outdoor use?

While this article focuses on indoor use, many floor LED screens come with IP ratings like IP65 or IP68, ensuring they can resist dust and low-pressure water sprays, making them suitable for damp or dusty environments.

How long do these screens last in high-traffic areas?

With proper maintenance, floor LED screens can maintain over 90% brightness for many years, even in high-traffic areas, thanks to their durable coatings and structural reinforcements.

Table of Contents

- Engineering Durability: How Floor LED Screens Withstand Heavy Foot Traffic

- Understanding Load Ratings and Pressure Tolerance Standards

- Impact and Crush Resistance Testing for Commercial Floor LED Screens

- Real-World Performance on Stages, Runways, and Public Floors

- Surface Materials and Anti-Scratch Technologies in Floor LED Screens

- Environmental Protection and Operational Stability in Demanding Conditions

- Proven Applications and Reliability of Floor LED Screens in Real-World Settings

- FAQ