Structural Engineering Challenges in Curved LED Integration

Understanding the Fundamental Challenge of Translating Flat LED Technology Into Spherical Forms

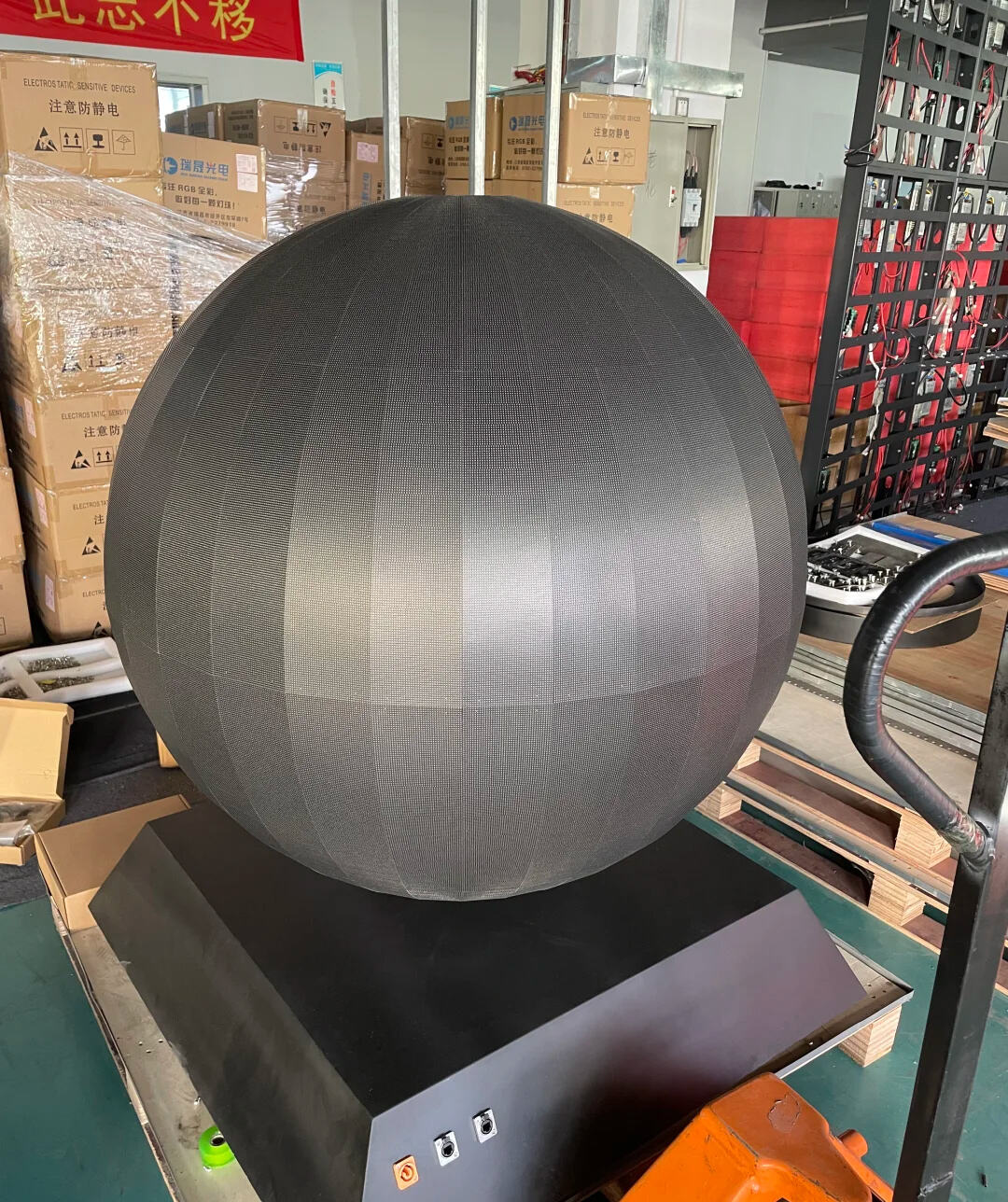

Designing LED displays that form perfect spheres means completely overhauling how we approach something that's been made for flat screens since day one. Most standard LED setups rely on stiff PCBs and those metal frames everyone knows, all meant for hanging straight on walls or ceilings. When trying to curve these components into a ball shape though, things get complicated fast. The curves mess with how everything lines up, leaving annoying spaces or making panels overlap where they shouldn't. Take a look at any regular LED screen and you'll find around 4.2 kilometers worth of wiring packed into just 10 square meters according to last year's Electronics Manufacturing Journal report. Now imagine trying to bend all that spaghetti through three dimensions without breaking anything. It's no wonder manufacturers struggle so much with this transition from flat to round displays.

How Structural Engineering Complicates Rigid Component Integration on Curved Geometry

The stress on curved display structures can jump anywhere from 180% to 300% higher than what we see in flat setups. One major problem comes from differences in how materials expand when heated. Aluminum frames expand at about 23 micrometers per meter per degree Celsius while composite printed circuit boards only expand between 15 and 18 micrometers under the same conditions. This mismatch creates real issues with shear forces across those curved surfaces. The pressure distribution isn't uniform either. Units placed toward the top of the curve actually handle around 12 to 15 percent less compression force compared to those sitting near the middle or bottom sections. Getting everything aligned correctly requires incredible attention to detail. Mounting has to stay within plus or minus 0.05 millimeters tolerance, which is four times stricter than the standard 0.2 mm allowance for flat panels. This level of precision makes installation much more challenging for curved displays.

Irregular Load Distribution and Frame Design: Balancing Weight and Stress Across Non-Uniform Surfaces

Looking at how weight gets distributed shows some real hotspots around the 35 degree mark on these spherical displays. The areas near the equator experience pressures reaching about 22 kilograms per square centimeter, which is actually more than triple what we see at the poles, where it's only about 6 kg/cm². Handling this kind of uneven load requires some clever engineering solutions. Most designers turn to specialized support frameworks like radial trusses, those cool geodesic structures we've seen before, and sometimes even combinations of different methods known as hybrid tensegrity designs. These approaches help distribute the forces more evenly across the entire structure.

| Design Strategy | Stress Reduction | Weight Impact |

|---|---|---|

| Radial truss system | 34% | +18% |

| Geodesic frame | 28% | +9% |

| Hybrid tensegrity | 41% | +22% |

These solutions redistribute mechanical loads while maintaining structural integrity, though often at the cost of added weight.

The Role of Material Flexibility and Mechanical Joints in Mitigating Structural Strain

The latest developments in silicone embedded LEDs that can actually survive being bent at 180 degrees along with rotational slip joints have made these systems much tougher when dealing with dynamic loads. The flexibility of these parts lets spherical displays cope with vibrations reaching 5.7g forces, which is pretty impressive compared to old school rigid setups where performance dropped off dramatically. We're talking about a 240% boost in handling capability here. For those wondering about specifics, adaptive ball joints give about plus or minus 8 degrees of angular movement. This allows modules to line up properly on all sorts of complicated curves without losing track of their position. Pixel accuracy stays within half a millimeter between points too (<0.4mm difference). So even when temperatures fluctuate during operation, viewers won't notice any breaks in the image quality across the display surface.

Pixel Pitch Variation and Image Distortion on Spherical Surfaces

Why Uniform Pixel Pitch Is Impossible in Spherical LED Display Layouts

The shape of a sphere just makes it impossible to get even pixel spacing everywhere on its surface. Flat displays have those neat grids where everything lines up perfectly, but when we try to map pixels onto a ball, things start getting squished at the top and bottom while stretching out around the middle. We're talking about differences in pixel density that can swing as much as 55% depending on where you look. Some premium setups actually measure between 28 and 62 pixels per inch according to recent data from the 2025 Display Optimization Report. That kind of inconsistency really messes with picture quality, so engineers developed special software solutions. These curvature compensation tools basically tweak how images are displayed based on exactly where they appear on the curved surface, trying to keep visuals looking sharp no matter where someone happens to be standing.

Geometric Distortion on Curved Surfaces and Its Impact on Image Clarity

When dealing with spherical surfaces, the way they bend light naturally causes problems for regular 2D content. Just look at what happens to text it stretches out around the middle but gets squished at the top and bottom. Circles? They end up looking like ovals instead. A recent projection mapping research from 2024 found something interesting too most people find these warped images pretty annoying when there's over 15% distortion. That explains why so many folks complain about those awkward visuals. To fix this issue, manufacturers have developed special tricks like fisheye corrections and UV mapping methods. These approaches basically twist the original content before displaying it, so everything lines up properly with how the curved screen actually looks to our eyes. Pretty clever workaround really.

Managing Resolution and Pixel Density for Optimal Visual Output

When it comes to getting the best visuals on screens with different pixel densities, there are basically three approaches that work well. First up is adaptive pixel clustering where they use those small pitch modules ranging from P1.2 to P2.5 in areas where the screen curves sharply. Then there's this thing called dynamic brightness scaling that adjusts light output between 12 and 18 percent to hide any visible differences in how densely packed the pixels are. And finally, we have AI powered warping technology. This one is pretty cool because it uses special neural networks that were trained specifically for spherical shapes to actually reshape what appears on the screen as needed, all while keeping everything looking smooth and natural in real time.

Case Study: Pixel Mapping Discrepancies in Large-Scale Spherical Installations

The massive 12 meter LED sphere at Dubai's Expo 2030 pavilion had some serious image issues at first, showing about 23% warping because the content wasn't mapped correctly. The engineering team fixed this problem through several approaches. They created a detailed 3D UV map of the entire spherical surface, applied those fancy NURBS correction profiles everyone talks about in computer graphics, and worked on blending edges across all 2,400 individual panels. After they calibrated everything properly, tests showed an impressive 94% drop in visual distortion. The seams where panels meet are now almost invisible, with alignment errors down to just 1.8mm or less. Pretty remarkable work considering the scale of the installation.

Module Alignment and Seamless Visual Continuity

Curved Panel Alignment Challenges in Achieving Seamless Visual Flow and Uniformity

Getting those smooth visuals right on a spherical LED display really comes down to getting those modular panels aligned just so. Even tiny angular shifts of around half a degree can create noticeable problems like visible gaps between panels, images appearing twice, or areas where brightness levels don't match up. Tech crews typically work with laser guides and those fancy six-axis adjustment mechanisms to get everything lined up properly during installation. But there's still one last step after all that hardware work. The software does the final fine tuning, checking anywhere from 12 to 14 different factors such as how edges blend together, whether colors look consistent across the whole surface, and how bright things appear at different points. This software magic helps bring everything into perfect alignment, often adjusting things down to fractions of a millimeter for that truly seamless effect we're aiming for.

Manufacturing Consistently Shaped Modular Panels for Spherical LED Displays

Creating large numbers of perfectly curved panels that are all exactly the same shape is no easy task. Even though CNC milled molds usually stick pretty close to their ±0.2mm tolerance specs, those tiny differences start to add up when dealing with curved surfaces, eventually creating noticeable gaps between panels. Smart companies now incorporate 3D scanning right into their manufacturing process so they can check each panel's curve against strict 0.15mm standards. There's another tricky aspect too: getting the thermal expansion rates to match between aluminum frames and LED materials. Aluminum expands at around 23 x 10^-6 per degree Celsius, which means if this doesn't align properly with the LED substrate material, panels will warp when exposed to extreme temperatures ranging from -30°C down to 50°C. Getting these coefficients right ensures panels stay stable and true over time, which matters a lot for installations that need to last years without maintenance issues.

Trade-Offs Between Modularity and Seam Visibility in Spherical Designs

There's always this balancing act designers have to manage between how easy something is to maintain versus looking seamless visually. When they go with smaller panels around 30 by 30 centimeters, one person can handle maintenance work but those panels leave behind pretty obvious gaps measuring about 3 to 5 millimeters. On the flip side, bigger panels at 100cm square make those lines almost disappear down to less than 1mm, though replacing them becomes a job needing heavy equipment like cranes. Some manufacturers have found success with a middle ground solution: trapezoidal panels sized around 60cm that lock together at their edges. These typically result in about 1.2mm wide seams and still let technicians replace them on site without special tools. The latest advancement comes from micro LED tech with pitches as small as 0.4mm or so. This allows for clever masking techniques along panel edges that actually hide roughly 8 out of 10 structural seams while keeping heat dissipation properties intact.

Software Mapping and Real-Time Calibration for Non-Linear Geometry

The challenge of content mapping on non-linear spherical LED surfaces

Getting 2D content to work properly on spherical LED displays is no small challenge because of the inherent geometric distortions involved. Flat screen technology just doesn't translate well when applied to round surfaces. Spherical displays need to handle those tricky radial pixel shifts and deal with viewers looking at them from all sorts of angles. What looks good on a standard rectangle gets messed up when mapped across different parts of a sphere, often stretching or compressing visuals in ways that create noticeable alignment problems, sometimes as bad as 18% off in the outer edges. That's why most professionals rely on special mapping software to warp images ahead of time, basically twisting what we see so it appears correct despite the curved surface it's projected onto.

Image calibration and warping techniques for accurate spherical rendering

The latest warping engines work their magic by making on the fly adjustments through these fancy parametric surface models. They tweak both the shape and brightness so everything looks right even when curved surfaces throw things off. Take those pesky edge pixels for example they usually get about a 20 something percent bump in brightness just to keep them looking as bright as what's happening in the middle area where our eyes naturally focus. That helps fight against how light tends to fade out at the edges. These days most calibration equipment actually pulls in photogrammetry information too. This lets it fix up colors and adjust white balance all around the hemisphere. The result? Images that stay consistent no matter where someone happens to be looking from. Pretty clever stuff if you ask me.

Processing power and data demands for real-time visual correction

Spherical LED displays need about 3.8 times more computing power compared to regular flat panels because they involve complex coordinate transformations for proper image rendering. Imagine a sphere with 10 meters across showing 4K resolution images while maintaining 10-bit color depth - this setup would require roughly 14 gigabytes per second of raw data bandwidth without compression. Recent advances in GPU technology with ray tracing capabilities have cut down those pesky edge mapping delays by around 40 percent, which makes everything look much smoother when displayed in real time according to research published last year on ScienceDirect.

Trend: AI-driven adaptation for dynamic content on spherical LED displays

Artificial neural networks have started predicting the best ways pixels should move when tracking objects over uneven surfaces. The machine learning models we've trained using 360 degree video data cut down the time needed for manual calibration by about two thirds. At the same time they make the motion look clearer and less blurry overall. What's interesting is how these smart systems adjust their rendering settings automatically depending on what kind of content they're dealing with. We see this happening whether it's fast paced sports footage, digital art installations, or even visualizations of space phenomena. The result stays consistently sharp and detailed throughout the entire round display area.

Thermal Management, Power Efficiency, and Maintenance Access

Heat Dissipation Challenges in Sealed Spherical LED Enclosures

The main problem with spherical LED displays is managing all that heat they generate since they're basically sealed units. Flat panels have nice open spaces for air to flow through, but these round ones trap heat right next to the delicate circuitry inside. Some thermal imaging experiments actually found temperature differences of over 28 degrees Celsius from one side of the sphere to the other. And this kind of hot spot creates real problems for the LEDs themselves. Tests done in controlled environments showed that the brightness starts fading away about 34% quicker than what we see in regular flat screen displays running at the same power levels. Makes sense when you think about how much stress those components are under in such a compact space.

Active vs. Passive Cooling Solutions in Compact Spherical Geometries

When it comes to cooling options, engineers face a tough decision between active and passive approaches, both having their own set of pros and cons. Active cooling involves things like forced air fans and duct systems which definitely get rid of more heat, though they come at a cost. These setups typically add around 18 to 22 percent extra weight and eat up about a quarter of what the display uses for power overall. On the flip side, passive cooling with copper heat sinks means no moving parts to worry about or maintain, but getting them to work right is another story. They need to make contact with those LED modules down to the millimeter, which becomes pretty tricky when dealing with those curved spherical frames that just won't lie flat.

Optimizing Airflow Within Constrained Spherical Frames

Manufacturers looking to boost passive cooling performance often turn to computational fluid dynamics or CFD for simulating how air moves inside equipment. Some interesting developments lately include those spiral shaped baffles that actually direct airflow along these curved paths, which seems to cut down on hot spots quite effectively according to tests showing around a 40% reduction in some cases. The catch though is that these advanced airflow solutions take up about 15 to 20 percent extra space inside the unit. That creates problems when customers want their cooling systems to fit into tight spaces or when trying to maximize rack density in data centers and industrial facilities where every inch counts.

Power Efficiency and Maintenance Accessibility in Elevated Spherical Installations

The high efficiency drivers we're seeing these days convert electricity at around 93 to 96 percent, which definitely cuts down on heat production. But there's a catch when it comes to maintenance for those permanently installed overhead systems. Take a look at those big spherical displays mounted in stadiums. Technicians need almost five times longer to swap out modules compared to regular flat wall installations. And guess what? About two thirds of all maintenance expenses come from needing special rigging gear. Some new quick detach panel systems are coming onto the market though. Manufacturers claim these can slash service time in half without compromising how sturdy the structure is or letting moisture and dust get inside. Time will tell if they actually work as well as promised in practice.

Frequently Asked Questions

Why are spherical LED displays more challenging to design than flat ones?

Spherical LED displays pose structural challenges due to their shape, requiring components to bend in three dimensions, which is more complex than flat displays that rely on linear alignment.

What materials are typically used to construct spherical LED display frames?

Typical materials include aluminum for frames, which can expand under temperature changes, and composite printed circuit boards that need careful alignment to handle curved surfaces.

How do engineers manage pixel distortion on spherical surfaces?

Engineers employ curvature compensation tools, fisheye corrections, and UV mapping methods to adjust images, maintaining clarity despite the curved surface.

What advances help manage heat in spherical LED displays?

Active cooling systems using fans and ducts are effective but add weight and power consumption, while passive cooling with heat sinks is lighter but requires precise fitting to be effective.

How do curvatures impact pixel pitch uniformity?

Spherical surfaces inherently cause pixel pitch variances due to uneven stretching, making it impossible to maintain uniform pixel spacing across the entire display.

Table of Contents

-

Structural Engineering Challenges in Curved LED Integration

- Understanding the Fundamental Challenge of Translating Flat LED Technology Into Spherical Forms

- How Structural Engineering Complicates Rigid Component Integration on Curved Geometry

- Irregular Load Distribution and Frame Design: Balancing Weight and Stress Across Non-Uniform Surfaces

- The Role of Material Flexibility and Mechanical Joints in Mitigating Structural Strain

- Pixel Pitch Variation and Image Distortion on Spherical Surfaces

- Module Alignment and Seamless Visual Continuity

- Software Mapping and Real-Time Calibration for Non-Linear Geometry

- Thermal Management, Power Efficiency, and Maintenance Access

-

Frequently Asked Questions

- Why are spherical LED displays more challenging to design than flat ones?

- What materials are typically used to construct spherical LED display frames?

- How do engineers manage pixel distortion on spherical surfaces?

- What advances help manage heat in spherical LED displays?

- How do curvatures impact pixel pitch uniformity?